Hearing aid earmolds play a crucial role in hearing health, serving as a personalized bridge between advanced hearing technology and your unique ear structure. These small yet crucial components ensure effective sound transmission while providing comfort and stability.

Mastering the basics of hearing aid earmolds can significantly enhance your everyday listening experience. In this guide, we’ll delve into the evolution of hearing aid earmolds, their various designs, materials, fitting procedures, benefits, potential challenges, and maintenance strategies.

The Evolution of Hearing Aid Earmolds

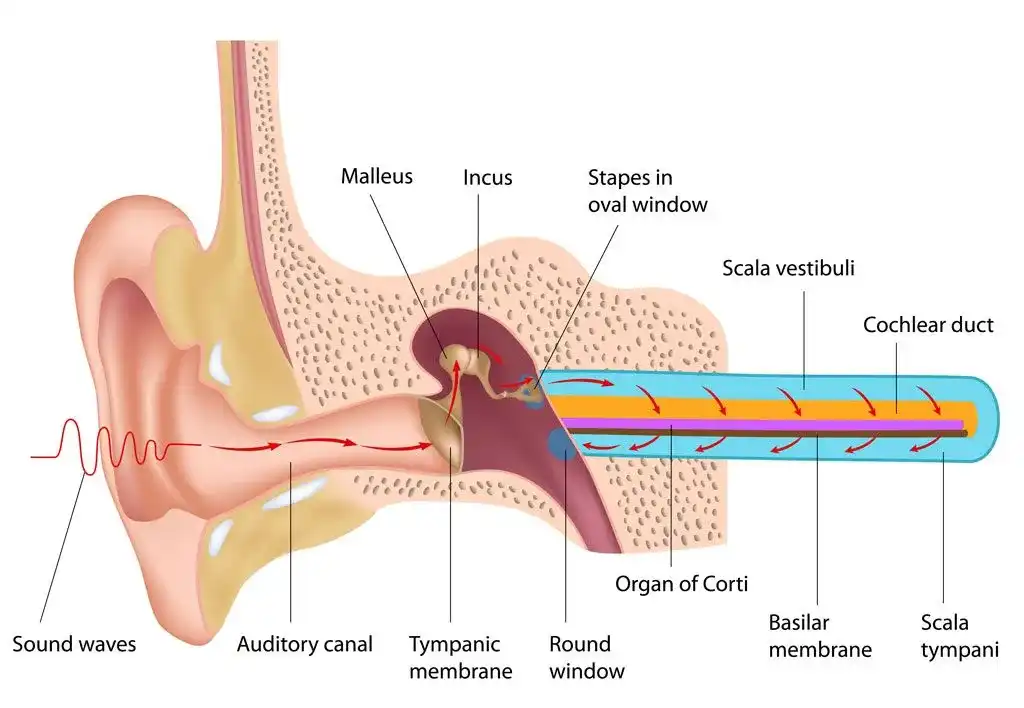

The story of hearing aid earmolds begins centuries ago and is intertwined with the broader history of hearing aids. Early attempts at sound amplification date back to the 17th century, when people used simple ear trumpets—funnel-shaped tools made of metal or animal horn—to direct sound waves into the ear.

By the late 19th century, the invention of the telephone sparked innovations in amplification technology, leading to the first electric hearing aids in the early 20th century. However, it wasn’t until 1923 that the first patented custom earmold was introduced. Designed by Halsey A. Frederick and transferred to Western Electric, it marked a shift toward personalized fit.

In the digital age, advances in materials and manufacturing processes also revolutionized earmolds. The shift from bulky vacuum tube devices to compact digital processors in the 1990s and early 2000s enabled more precise customization. Today, 3D printing and laser scanning technologies enable the rapid production of custom-fitted earmolds, improving sound quality and user satisfaction.

This development highlights how hearing aid earmolds are adapting to the demands of modern lifestyles, from low-profile designs for professionals to rugged options for active users.

Different types of hearing aid earmolds

Hearing aid earmolds come in a variety of styles, each engineered to address specific hearing needs, ear shapes, and lifestyle preferences. Selecting the right type is key to achieving optimal sound quality and comfort.

- Full-shell earmolds: These earmolds cover the entire outer ear (concha) and extend into the ear canal. They are ideal for severe hearing loss because they provide a strong acoustic seal, minimize feedback, and maximize amplification. Full-shell earmolds are generally recommended for users with higher power requirements and are durable, but they may feel bulkier.

- Half-shell earmolds: A more compact version of the full-shell earmold, these earmolds only fill half of the concha while still allowing access to the ear canal. They strike a balance between a tight seal and openness and are suitable for those with moderate hearing loss. Compared to full-shell earmolds, users prefer these earmolds for their lighter weight and easier fit.

- Skeleton earmolds: These earmolds have a skeleton structure that contours to the concha without completely filling it, making them lightweight and discreet. They are ideal for those with mild to moderate hearing loss and allow for better airflow, thereby reducing the occlusion effect—the muffled feeling associated with hearing aids.

- Canal and Canal-Lock Earmolds: Canal earmolds are designed to fit directly into the ear canal, are compact, and fit deep into the ear canal for a comfortable fit. Canal-Lock Earmolds have a small extension for better positioning and prevent slipping during exercise. These earmolds are popular with active individuals or those seeking minimal visibility.

- CROS and Solid Earmold Options: CROS (Contralateral Signal Routing) earmolds are used for single-sided hearing aids, routing sound from the damaged ear to the better ear. Solid Earmolds, on the other hand, feature a simple tubular design that surrounds the receiver, providing basic protection and are suitable for use with receiver-in-the-canal (RIC) hearing aids.

To visualize the differences, consider this comparison table of earmold types based on key attributes:

| Earmold Type | Best For Hearing Loss Level | Comfort Level | Visibility | Acoustic Seal Strength |

|---|---|---|---|---|

| Full Shell | Severe | Medium | High | Excellent |

| Half Shell | Moderate | High | Medium | Good |

| Skeleton | Mild to Moderate | High | Low | Moderate |

| Canal | Mild | High | Very Low | Good |

| Canal Lock | Mild to Moderate | High | Low | Strong |

Hearing Aid Earmold Materials

The material choice for hearing aid earmolds affects everything from durability to skin compatibility. Common materials include acrylic, silicone, vinyl, and sometimes advanced composites. Acrylic is strong and durable, suitable for users who require a secure seal, but may not be as compatible with sensitive skin. Silicone is softer and more flexible, conforming to ear movement and generally providing a more comfortable fit, especially with severe ear loss exceeding 75 dB HL.

Vinyl offers a balance of flexibility and strength and is hypoallergenic, reducing the risk of irritation. Emerging materials, such as soft silicone blends, have antimicrobial properties that prevent moisture accumulation. Audiologists consider factors such as ear canal size, perspiration, and allergy history when selecting earmolds to prevent issues such as dermatitis.

Custom Hearing Aid Earmolds

Creating custom hearing aid earmolds requires a precise, non-invasive procedure, beginning with the earmold. The audiologist uses a soft, putty-like substance to create a mold based on the shape of your ear canal and concha, ensuring every contour is accurately captured. This mold is then scanned or sent to a laboratory, where a technician uses the 3D model to create an earmold to ensure precision.

This process typically takes 1-2 weeks, followed by a fitting to verify fit, seal, and sound quality. Adjustments may include adding vents to relieve pressure or horns to enhance high-frequency sounds. Custom earmolds are superior to standard earmolds in reducing feedback and enhancing the perception of natural sound, especially in dynamic environments such as conversation or music.

Advantages of Using Hearing Aid Earmolds

Hearing aid earmolds offer many benefits. They deliver amplified audio directly to the eardrum, eliminating sound leakage and improving sound fidelity, which is crucial for clear speech understanding. They also provide a more secure fit, keep the device secure during exercise, and minimize occlusion for a more natural hearing experience.

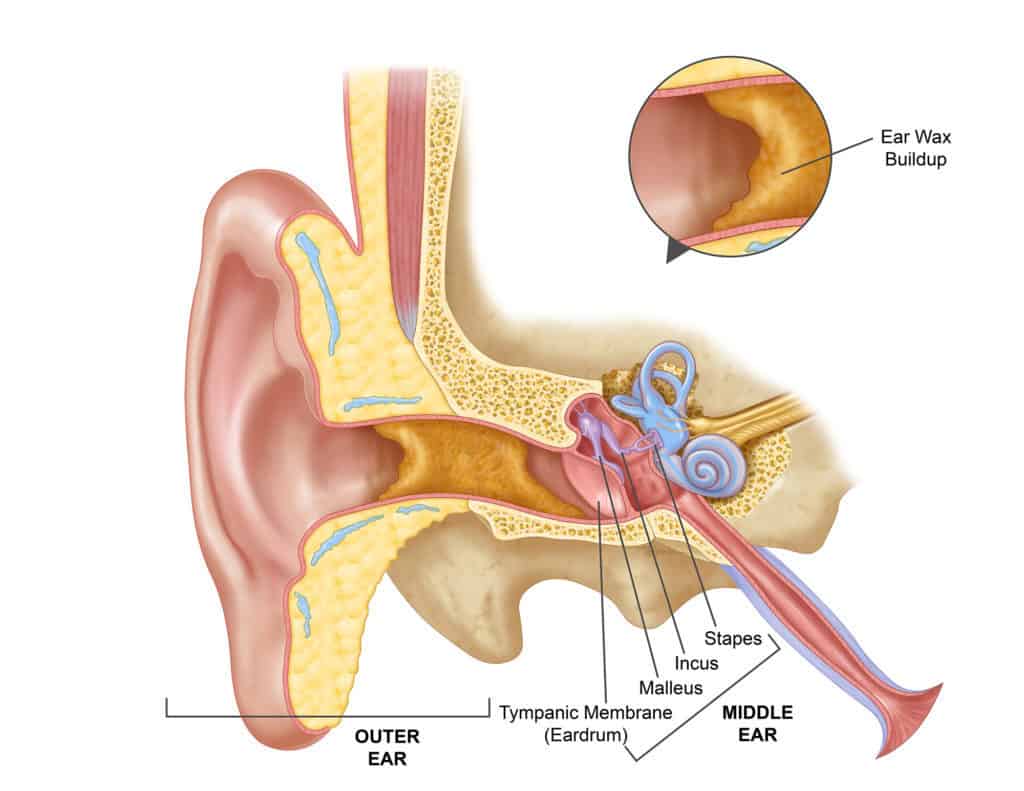

From a health perspective, well-fitting earmolds prevent ear canal irritation, promote ventilation, and prevent earwax buildup. For users with more severe hearing loss, earmolds can safely provide higher levels of amplification. Studies have shown that custom earmolds can increase user satisfaction by up to 30% compared to standard earmuffs, thereby improving compliance and overall quality of life.

Hearing Aid Earmold FAQs

While hearing aid earmolds offer many advantages, they also present some challenges. Feedback (whistling) often stems from a poor seal and can be addressed through acoustic improvements such as refitting or adding vents. Material allergies or incorrect fit can cause discomfort; switching to a softer silicone earmold often helps.

Moisture accumulation is another issue, especially in humid climates, causing muffled sound or device corrosion. Regular cleaning and the use of a dehumidifier can alleviate this. For children, changes in fit due to growth and development may require regular replacement. If persistent problems persist, consult an audiologist to avoid exacerbating hearing problems.

Tips for Extending the Care and Maintenance of Hearing Aid Earmolds

Proper care is crucial to maximizing the life of hearing aid earmolds. With proper care, earmolds can last up to 2-5 years. Wipe the earmolds daily with a soft cloth or a dedicated brush to remove earwax and debris. Avoid using harsh chemicals; mild soap and water will provide a deep clean, then dry thoroughly.

Store earmolds in a dry box away from heat or sunlight to prevent warping. Inspect the earmolds monthly for cracks or discoloration, which may indicate a need for professional evaluation. For frequent hearing aid users, consider adding a protective coating or annual refurbishment. Following these maintenance procedures will not only extend the life of your earmolds but also ensure their consistent performance.

Custom Earmolds vs. Standard Earmolds: Which is Better for You?

Custom hearing aid earmolds are precisely tailored to your ear shape, providing superior fit and sound quality, and are ideal for complex hearing conditions. Standard earmolds, such as spherical earmolds, are pre-made and easier to obtain, but can slip or cause tinnitus, especially if your ear shape is irregular.

While custom earmolds have a higher upfront cost, they can reduce long-term adjustments and improve results. Standard earmolds are suitable for mild hearing loss or as a trial. Ultimately, an audiologist will conduct an assessment based on your hearing level and lifestyle to guide your choice.

Other Applications for Earmolds

Earmold technology has applications far beyond traditional hearing aids. Musicians use custom earmolds for in-ear monitors to maintain sound quality while resisting high-volume interference. Swimmers and industrial workers use earmolds for noise reduction and waterproofing. Even in medical settings, earmolds have been adapted for use in tinnitus management devices, demonstrating their versatility.

Summary

Hearing aid earmolds are more than just accessories; they are an integral part of effective hearing support, evolving from basic hearing aids to sophisticated, user-centered solutions. Understanding earmold types, materials, and care methods can help optimize your hearing journey.

If your hearing is changing, schedule a consultation with a certified audiologist to explore a personalized plan.